Application:

PET Bottle Recycling

Condition:

New

Automatic Grade:

Automatic

Plastic Type:

PET, PET PP

Production Capacity (kg/h):

500 - 2000

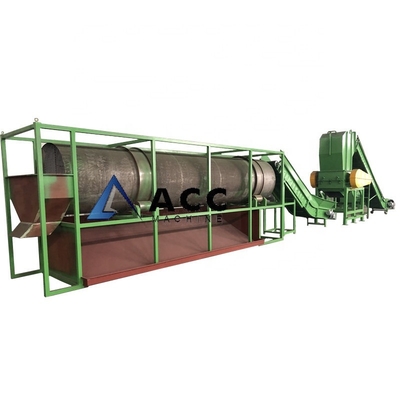

Machine Type:

PET Bottle Washing Line

Equipment List:

Trommer, Pre-washer, Bale Opener, Dewatering Machine, Floating Washing Tank, Hot Air Dryer, Frication Washer, Label Separator, Label Remover, Hot Washing Tank

Max.Production Capacity (kg/h):

2000

Voltage:

380v 50hz 3phase

Dimension(L*W*H):

12000/3600/2800 MM

Power (kW):

110

Weight (T):

12

Warranty:

1 Year

Key Selling Points:

Multifunctional

Video outgoing-inspection:

Provided

Applicable Industries:

Hotels, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Printing Shops, Energy & Mining

Showroom Location:

France, Philippines, Saudi Arabia, Indonesia, India, Mexico, Morocco, Argentina, South Korea, Sri Lanka, South Africa, Nigeria

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

PLC, Bearing, Gearbox, Motor

Name:

Plastic Pet Bottle Recycling Crushing

Material Processed:

Bottle Flakes

Final product:

Clean PET Bottle Flakes

Color:

Customer Choice

Keywords:

PET Flakes Recycling Machine

Type:

PET Bottle Plastic Recycling Line

Material:

Stainless Steel 304

Raw material:

Waste PE PP PET Bottle

Capacity:

100kg/h-1000kg/h

After-sales Service Provided:

Video technical support, Field installation, commissioning and training, Online support

After Warranty Service:

Video technical support, Online support, Field maintenance and repair service

Local Service Location:

United States, Brazil, Indonesia, Pakistan, Mexico, Russia, Malaysia, Morocco, Argentina, Colombia, Kazakhstan, Ukraine

Zertifizierung:

CE

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!